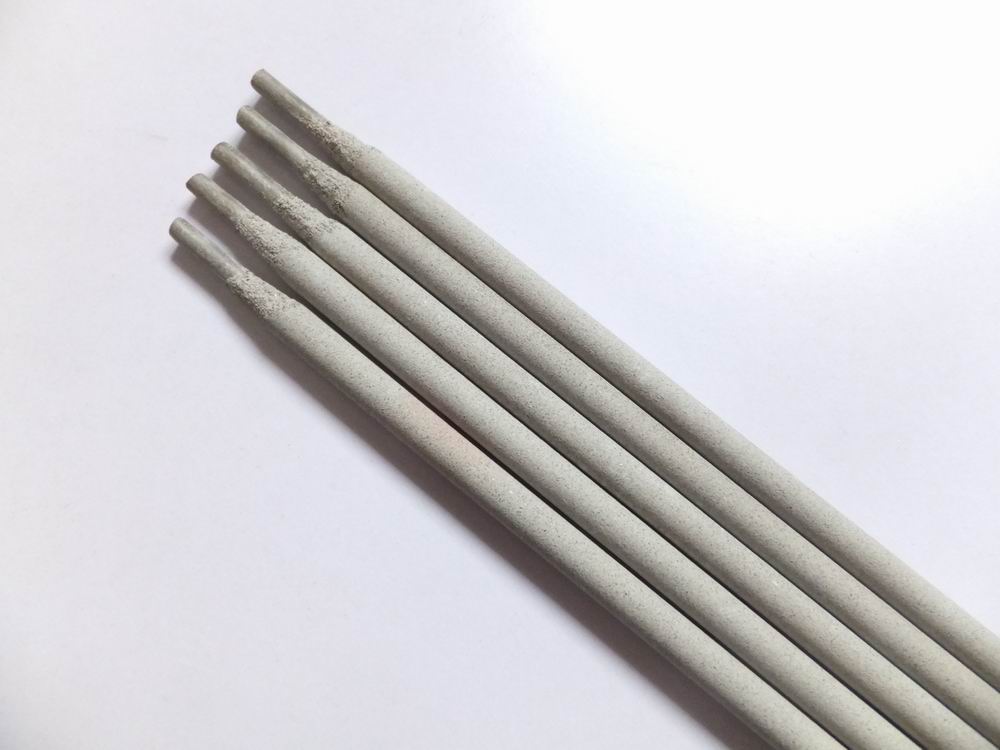

nickel welding rod

We are manufacturer and supplier of nickel welding rod. We have rich experience in manufacturing nickel welding rod. From raw materials to finished products, we strictly control every production step.

We dedicate ourselves to manufacture and supply of nickel welding rod with nice service.If you need nickel welding rod, please email us.

Retaled "Nickel Welding Rod" Keywords

Retaled blog

Pure nickel electrode NOTES---2013-08-30

Pure nickel electrode NOTES1 Welding electrodes shall be about 150 ℃ baking 1h. 2 For withstand stresses and shocks and other important casting structure, the electrode should not be used. 3 small thin-walled castings parts of the defects Nickel Alloy Welding Electrodes can be little stiffness without preheating welding, and general weldment to be preheated to 400 ℃, insulation slow cooling after welding, the welding at a possible cutting. Description: Z238 is a low-carbon steel core, strong graphite type coating iron rod, because a certain amount of ductile agent, so that the deposited metal graphite in the cooling process spherical precipitates, both AC and DC . Uses: Used for welding ductile iron.

var addthis_config = {"data_track_addressbar":true};

Nickel electrode - nickel-base alloy electrode---2013-08-30

Low hydrogen type 5 corrosion resistant alloy electrode, the weld has the right amount of molybdenum, niobium and other alloying elements, deposited metal has excellent crack resistance, DC reverse. For welding heat-resistant, corrosion resistant nickel-based alloys required, can also be used for some difficult welding alloys, welding dissimilar steels and heat-resistant alloys with low hydrogen electrode, the weld has the right amount of manganese, niobium and other alloying elements , deposited metal has excellent crack resistance, DC reverse. Welding heat-resistant,Nickel Alloy Welding Wire resistant nickel-based alloys requirements, such as Inconel 600, 601, etc., can also be used for some difficult to weld alloys, dissimilar steel welding and surfacing. Have the right amount of weld metal molybdenum, and crack resistance. Low hydrogen type Ni70Cr15 heat-resistant alloy electrode, the weld metal has the right amount of molybdenum, niobium and other alloying elements, deposited metal has excellent crack resistance, DCRP for welding heat-resistant, corrosion resistant nickel-base required alloys, can also be used for some difficult to weld alloys, dissimilar steels and low-hydrogen welding corrosion resistant nickel-chromium alloy electrode, the weld metal has good crack resistance and corrosion resistance, good weldability, using DC reverse, all-position welding. For nuclear power regulator, evaporator tube sheet welding joints can also be used in composite steel, dissimilar steel and the same type of nickel-based alloys welding.

var addthis_config = {"data_track_addressbar":true};

Nickel wire---2013-08-30

For nickel alloys, carbon steel, stainless steel and a low alloy steel welding, the main welding alloys for 625,601,802 and 9% nickel alloy welding for welding nickel-chromium-cobalt-molybdenum alloys and various high-temperature alloys pure nickel dissimilar welding industry for malleable iron and gray cast iron welding for nodular cast iron, ductile iron, malleable iron and gray cast iron welding Nickel Welding Electrodesused for their own and stainless steel, carbon steel, low alloy steel and various nickel alloy weldingNickel-chromium-molybdenum alloy for welding itself, or nickel-chromium-molybdenum alloy and steel and most other welding nickel-based alloys

var addthis_config = {"data_track_addressbar":true};

Nickel electrode---2013-08-30

Nickel electrodeNickel and nickel alloy electrode can be divided into five categories, namely commercially pure Ni, Ni-Cu, Ni-Cr-Fe, Ni-Mo and Ni-Cr-Mo. Each class can be divided into one or more types of electrodes. These Nickel Alloy Welding Electrodes electrodes are mainly used for welding nickel or high nickel alloys, and sometimes also be used for dissimilar metal welding or surfacing.

var addthis_config = {"data_track_addressbar":true};

Check for detail

Check for detail