| Replay: 1, the composition and role of the electrode

The electrode core welding (metal core) and drug skin

1) The core wire welding dedicated wire, and the main material of the composition of the weld metal. Welding when welding core role: as an electrode from the role of the conduction current and ignited arc. Second, is melted as a base material in the filler metal and melted together forming a weld. In order to ensure the weld quality, more stringent requirements on the chemical composition of the weld metal. Therefore, the core wire is specifically smelting, low content of carbon, silicon, sulfur, phosphorus content is extremely low.

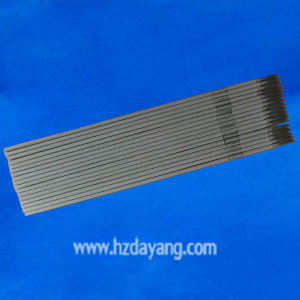

The diameter of the wire with the diameter of the core wire electrode diameter specifications Φ1.6 Φ2.5, Φ3.2, Φ4, Φ5 Φ6 mm several length ranging from 200-550 mm. And we Practice electrode diameter Φ3.2 mm, a length of 350 mm.

2) manual arc welding electrode medicine skin:

① mechanical protection: the use the drug skin is melted after the release of gas and the isolation of the formation of a slag air, to prevent the harmful gas into molten metal.

② metallurgical treatment effects: to place the harmful impurities (such as oxygen, hydrogen, sulfur, phosphorus) and add useful alloying elements, so that the weld to obtain a desirable chemical composition and mechanical requirements.

③ improve welding performance: Stable arc, low spatter, weld molding, easy off slag.

2, classification of welding electrodes

1) According to the nature of the electrode covering, the electrode can be divided into two categories of the acid electrode and basic electrode. Electrode the drug skin contains large amounts of acidic oxides (TiO2, SiO2, etc.) called acid electrode. The drug skin contains large amounts of alkaline oxide (CaO, Na2O, etc.) called alkaline electrode. Acid electrode AC and DC welding performance is better, but the mechanical properties of the weld, especially the poor impact toughness, applicable to the general low-carbon steel and low strength low-alloy structural steel welding is the most wide of the electrode. The basic electrode desulfurization dephosphorization ability the drug skin dehydrogenase role. Welded joints hydrogen content is very low, it is also referred to as low-hydrogen electrodes. Alkaline electrode welds with good crack resistance and mechanical properties, but poor process performance, general welding using DC power, mainly used in the structure (such as boilers, pressure vessels and alloy structural steel) welding.

2) electrodes of different purposes, the electrode can be divided into structural steel electrode (carbon steel electrode and low alloy welding rod), stainless steel welding rod, cast iron welding rod, heat-resistant steel welding electrodes, low temperature welding electrodes, welding electrodes, copper and copper alloys , nickel and nickel alloys, aluminum and aluminum alloys, etc., which is the most widely used structural steel electrode. |