welding assembly

We are the quality manufacturer of welding assembly from China. We export welding assembly, also provide OEM service of welding assembly for you.

Our welding assembly absolutely can fit your need with high quality and reasonable price. From raw materials to finished products, we strictly control every production step.

Any need of welding assembly, please email us.

Retaled "Welding Assembly" Keywords

Retaled blog

Welding classification---2013-09-03

Many types of welding methods , and new methods are still emerging, so how to conduct scientific classification welding method is a very important issue. Correct classification can not only help the reader understand, learn the characteristics of various Cast Iron Welding Electrode methods and nature , but also for scientists to develop new welding technique to provide a strong foundation. At present , domestic and foreign works of many types of welding methods taxonomy , varies. The manual begins with a simple classification of the existing descriptions and comments , and then propose a new classification method , discuss its principles and benefits. The volume and use it as the basis for the preparation of each chapter .

var addthis_config = {"data_track_addressbar":true};

equipped with welding methods require some welding equipment---2013-09-03

Include: welding power , welding mechanization mechanical system , control system and other auxiliary equipment. A power supply , the device complexity , cost, and so a direct impact on the economic benefits of the welding , the welding equipment welding method is to choose important factors must be considered . Welding current with alternating current power supply and DC power into two categories. General AC arc welding machine structure is relatively simple and low cost.Manual arc welding equipment required easiest , in addition to a power source , but only equipped with welding cables and welding electrode holder clamp can be. Should be given priority. MIG arc welding requires automatic welding , automatic trolleys and other mechanical equipment . Moreover, you should have protective gas supply system for conveying , through the cooling water supply system and the welding torch and so on. Vacuum electron beam welding to be equipped with high-voltage power supply, the vacuum chamber and specialized electron gun . Laser Aluminium Welding Wire requires a certain power lasers and focusing system . Therefore, these two methods should have specialized welding tooling and auxiliary equipment, the equipment is relatively complex , high power, and thus the cost is relatively high. Since a high voltage electron beam welding and X-ray radiation, so also there are certain safety precautions and prevent X-ray radiation shielding facilities.

var addthis_config = {"data_track_addressbar":true};

new developments in welding technology---2013-09-03

With the development of industry and science and technology , welding technology progress. Each chapter of this manual is only one of the more mature person to be introduced. But times are rapidly running wheels , manual impossible timely amendment added to reflect the forefront of welding technology situation , to fill this deficiency This section describes special welding technology trends.1 . Improve welding productivity is to promote the development Aluminium Welding Electrodes technology an important driving force(2) Improve preparation workshop mechanization and automation level is currently the world focus on the development direction of the advanced industrial countries3 welding process automation and intelligent is to improve the quality of welding stability , resolve an important direction for harsh working conditions4 continue to promote the development of new industries welding technology advances5 heat welding process research and development is to promote the development of the fundamental driving force6 energy-saving technology is a common concern

var addthis_config = {"data_track_addressbar":true};

Arc welding---2013-09-03

Arc welding is the most widely used welding methods . It includes : manual arc welding , submerged arc welding , gas tungsten arc welding , plasma arc welding , MIG welding and so on.Most electric arc between the electrode and the workpiece is burning arc as a heat source . In the formation of joints, may or may not use filler metal . The electrode used in the welding process molten welding wire , known as MIG arc welding , such as Tungsten Welding Electrode , submerged arc welding , gas-shielded arc welding , electric arc welding cored wire ; electrode used in the welding process does not melt the carbide or tungsten rod when called does not melt arc welding , such as gas tungsten arc welding , plasma arc welding and so on.

var addthis_config = {"data_track_addressbar":true};

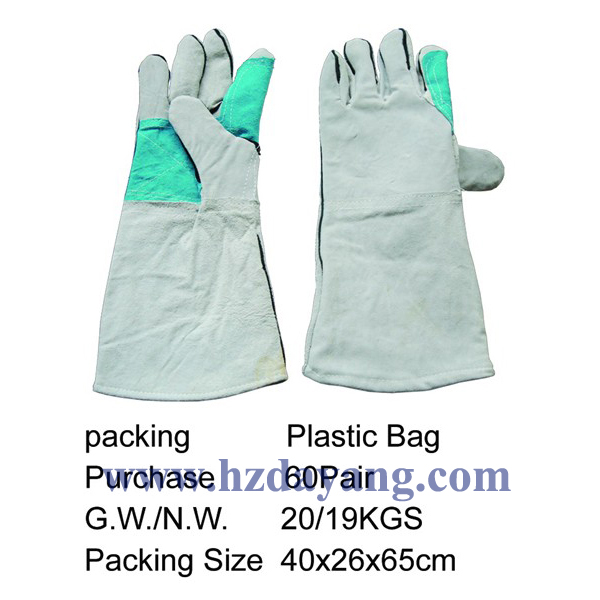

Check for detail

Check for detail