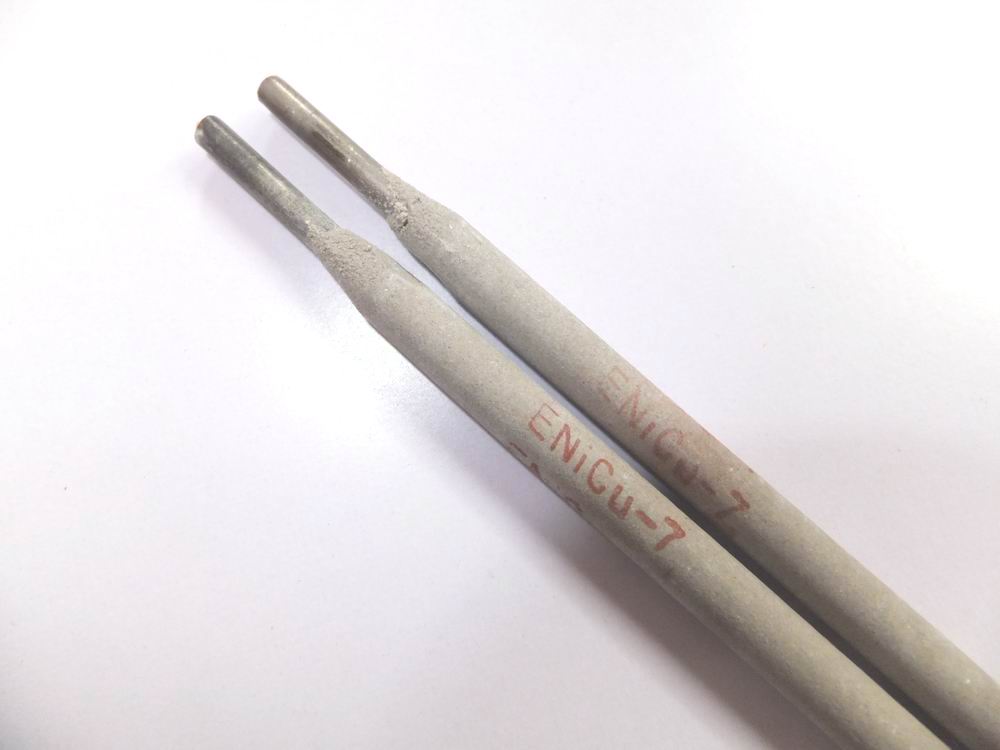

nickel alloy welding wire

Welcome to our product page of nickel alloy welding wire.

We are the quality manufacturer and supplier of nickel alloy welding wire. We have rich experience in manufacturing nickel alloy welding wire. From raw materials to finished products, we strictly control every production step.

We dedicate ourselves to manufacture and supply of nickel alloy welding wire with nice service.If you need nickel alloy welding wire, please send inquiry to us.

Retaled "Nickel Alloy Welding Wire" Keywords

Retaled blog

Nickel and nickel alloy electrode selection and use---2013-09-02

( 1 ) Nickel and nickel alloy electrode selection principle of nickel and nickel alloy electrode mainly based on the base material being welded alloy grades , chemical composition and use of environmental and other conditions used . Deposited metal electrode , the main chemical ingredient should be the main component of the base metal to be close in order to ensure the performance of welded joints and base metal considerably . However, considering the alloy in the arc welding losses, welding should also contain other Cast Iron Welding Electrode elements , in order to improve performance or seam welding performance.If you use the same ingredients electrode design requirements or did not reach a similar alloy composition suitable electrode , then the recommended use of high-performance one level electrode, in order to ensure that the weld performance is not less than the base metal .( 2 ) Nickel and nickel alloy electrode precautions for use① base metal preparation: before welding the base metal surface should be carefully cleared of oil , paint , dust and other dirt .② In order to prevent the holes, using a short -arc welding.③ The small welding current, welding without preheating , interpass temperature kept low (<150 ℃), in order to avoid overheating of the base material .④ welding rod swings to small, stay a little longer bead on both sides , in order to facilitate the pores and slag floats .Note ⑤ crater fill the crater to avoid crater cracks .⑥ nickel and nickel alloy microstructure of austenite , has a strong tendency to hot cracking in the weld fillet weld , the weld was required convex , so you can better prevent heat cracks .

var addthis_config = {"data_track_addressbar":true};

iron-nickel alloy---2013-09-02

Apart from iron-nickel alloy Invar , Kovar and permalloy , but also include the following alloys : (1) 68Fe +27 Ni +5 Mo and 53Fe +42 Ni +5 Mo, has a high thermal expansion coefficient , can be used bimetal thermostat , heat exchanger , and a variety of temperature adjusting means . (2) 46Ni +54 Fe, called on Low Alloy Steel Electrodes behalf of platinum , platinum same coefficient of expansion , has good corrosion resistance, in some cases can be used instead of platinum . (3) 42Ni +58 Fe, vacuum sealing can be used instead of platinum wire. (4) 36NJ +12 Cr +52 Fe, is a constant elastic alloys , thermo-elastic coefficient is equal to zero , commonly used for hair clips , watches balance wheel and precision instrument parts . Melting ingots , pressure processing .

var addthis_config = {"data_track_addressbar":true};

Nickel alloys---2013-09-02

Nickel-based alloys by adding other elements . 1905 system out of about 30% copper Monel (Monel) alloys, nickel alloys is earlier . Ni has good mechanical , physical and chemical properties by adding a suitable element to increase its oxidation resistance, corrosion resistance, high temperature strengthCarbon Steel Welding Electrodecertain physical properties. Nickel alloy materials can be used as electron tubes , precision alloy ( magnetic alloy , precision resistance alloys , electric alloys, etc. ) , nickel-based alloys and nickel-based high-temperature corrosion resistant alloys and shape memory alloys. Development in the energy , chemical, electronics , marine, aviation and aerospace sectors , nickel alloys have a wide range of applications .

var addthis_config = {"data_track_addressbar":true};

What types of nickel alloys---2013-09-02

Nickel-base superalloy . Major alloying elements are chromium, tungsten, molybdenum, cobalt, aluminum , titanium, boron , zirconium, etc. . Wherein the chromium as an anti- oxidation and anti- corrosion, strengthening effect from the other elements . At 650 ~ 1000 ℃ high temperature have high strength and resistance to oxidation and corrosion of gas is the most widely used high-temperature alloys , high temperature strength in the highest class of alloys. The talents are scarce mainly nickel alloy bars Cheng LinIn the steel network of excellence . For the manufacture of aircraft engine blades and rocket engines , nuclear reactors, high temperature energy conversion equipment parts . ② nickel-based corrosion resistant alloys . Aluminium Welding Electrodes are copper, chromium, molybdenum . Has a good overall performance, resistance to corrosion and stress corrosion of various acid . The first application is the nickel-copper alloy , also known as Monel ; addition to nickel-chromium alloys, nickel-molybdenum alloys, nickel- chromium-molybdenum alloy. For the manufacture of a variety of corrosion-resistant components. ③ resistant nickel-based alloys. Main alloying elements chromium, molybdenum , tungsten, but also contains small amounts of niobium , tantalum and indium . In addition to having wear resistance , its resistance to oxidation, corrosion , welding performance is good. Wear parts can be manufactured , can also be used as coating material , by means of welding and coating process to be coated on the other surface of the substrate . ④ nickel-based precision alloy . Including nickel-based soft magnetic alloys , nickel-based alloys and nickel-based precision resistance heating alloys. The most commonly used soft magnetic alloy containing 80% nickel- nickel alloy with Lin ChengPermalloy so , the maximum magnetic permeability and high initial permeability , low coercive force , in the electronics industry is important core material . Nickel-based alloy precision resistor main alloying elements chromium , aluminum, copper , this alloy has a Flux Cored Welding Wire, low temperature coefficient of resistivity and good corrosion resistance , for the production of resistors. Nickel-based heating alloys containing 20% of nickel chromium alloy with good oxidation resistance, corrosion resistance, can be a temperature of 1000 ~ 1100 ℃ long-term use . ⑤ nickel-based shape memory alloys. Ti- 50 (at)% nickel alloy . Its recovery temperature is 70 ℃, the shape memory effect. Small changes in the proportion of nickel titanium component , can reply to the temperature 30 ~ 100 ℃ range. Used for manufacture of spacecraft used automatically open structure, the aerospace industry with the self- excitation fasteners used on biomedical artificial heart motors.

var addthis_config = {"data_track_addressbar":true};

Check for detail

Check for detail