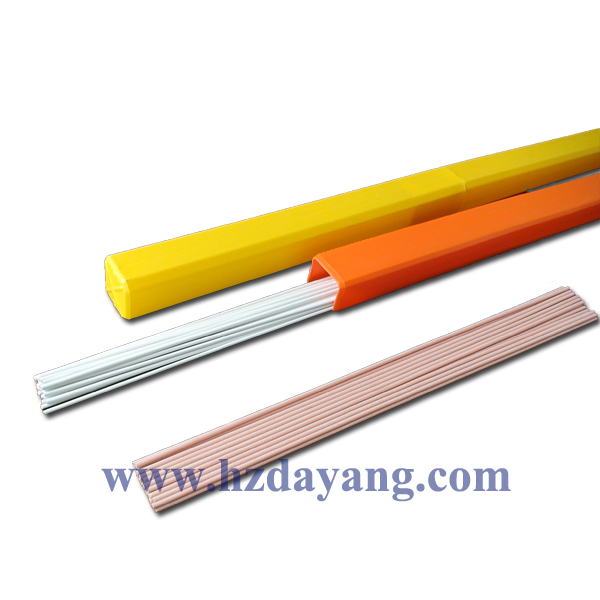

brazing alloy

Welcome to our product page of brazing alloy.

We are the quality manufacturer and supplier of brazing alloy. We have rich experience in manufacturing brazing alloy. From raw materials to finished products, we strictly control every production step.

We dedicate ourselves to manufacture and supply of brazing alloy with nice service.If you need brazing alloy, please send inquiry to us.

Retaled "Brazing Alloy" Keywords

Retaled blog

Aluminum vacuum brazing---2013-09-02

Non-aluminum alloy brazing sheet type vacuum brazing, identified various elements on Si solder wettability. Add 1 ~ 1.5% Mg, can lead to satisfactory results. Then add a small amount of bismuth, can further improve the solder wettability and reduce the requirements for the degreeCopper Brazing Alloys. The workpiece into the box, and then placed in a vacuum furnace heating cartridge brazing, can significantly improve the quality of brazing. To solder sealing flow can be in the soldering zone plus a small amount of magnesium. In this paper, the role Brazing Alloys magnesium were studied. Mg vapor through the oxide film is slit, with the aluminum alloy occurs, molten solder along the surface spreading of alloying, and the oxide film is raised, thereby generating wetted. Vacuum brazing solder joint quality can be obtained.

var addthis_config = {"data_track_addressbar":true};

carbide brazed---2013-09-02

carbide brazedLong before brazing welding surface to be cleaned. Welding, preheating should pay attention to Copper Brazing Alloys eliminate porosity, slag, welding plump! Consent, but also pay attention to choose the right brazing, soldering temperature. In general, solder alloy

var addthis_config = {"data_track_addressbar":true};

Brazing---2013-09-02

With a lower melting point than the base metal material as the brazing filler metal with a liquid wetting the base metal and solder filling the gap and the workpiece interface, and the base material to mutual diffusion soldering method. Deformation brazing, the joint is smooth and beautiful, suitable for welding sophisticated, complex and components composed of different materials, such as honeycomb panels, turbine blades, carbide tool and the printed circuit board. Before Copper Brazing Alloys workpiece must be strict and meticulous processing and cleaning, to remove oil and over-thick oxide film, ensure that the interface assembly space. General requirements for clearance of 0.01 to 0.1 mm.

var addthis_config = {"data_track_addressbar":true};

brazing characteristics---2013-09-02

brazing characteristics(1) low temperature brazing, the joint is smooth, small changes in structure and mechanical properties, deformation, precise size of the workpiece.(2) the dissimilar metal welding, dissimilar materials can also be welded, and the difference in thickness of the workpiece is not critical.(3) Some welding Brazing Alloys method can simultaneously multiple weldments, multi-joint, high productivity.(4) brazing equipment is simple, low investment costs.(5) The joint strength is low, the heat resistance is poor, and the whole Qing demanding welding, brazing expensive.

var addthis_config = {"data_track_addressbar":true};

Check for detail

Check for detail